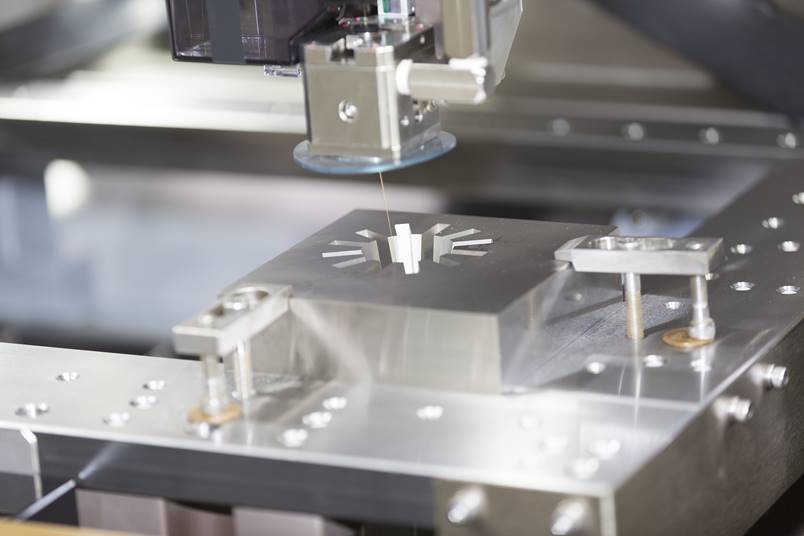

Precision Machining & Wire Services

Our Machining & Wire Burning Services

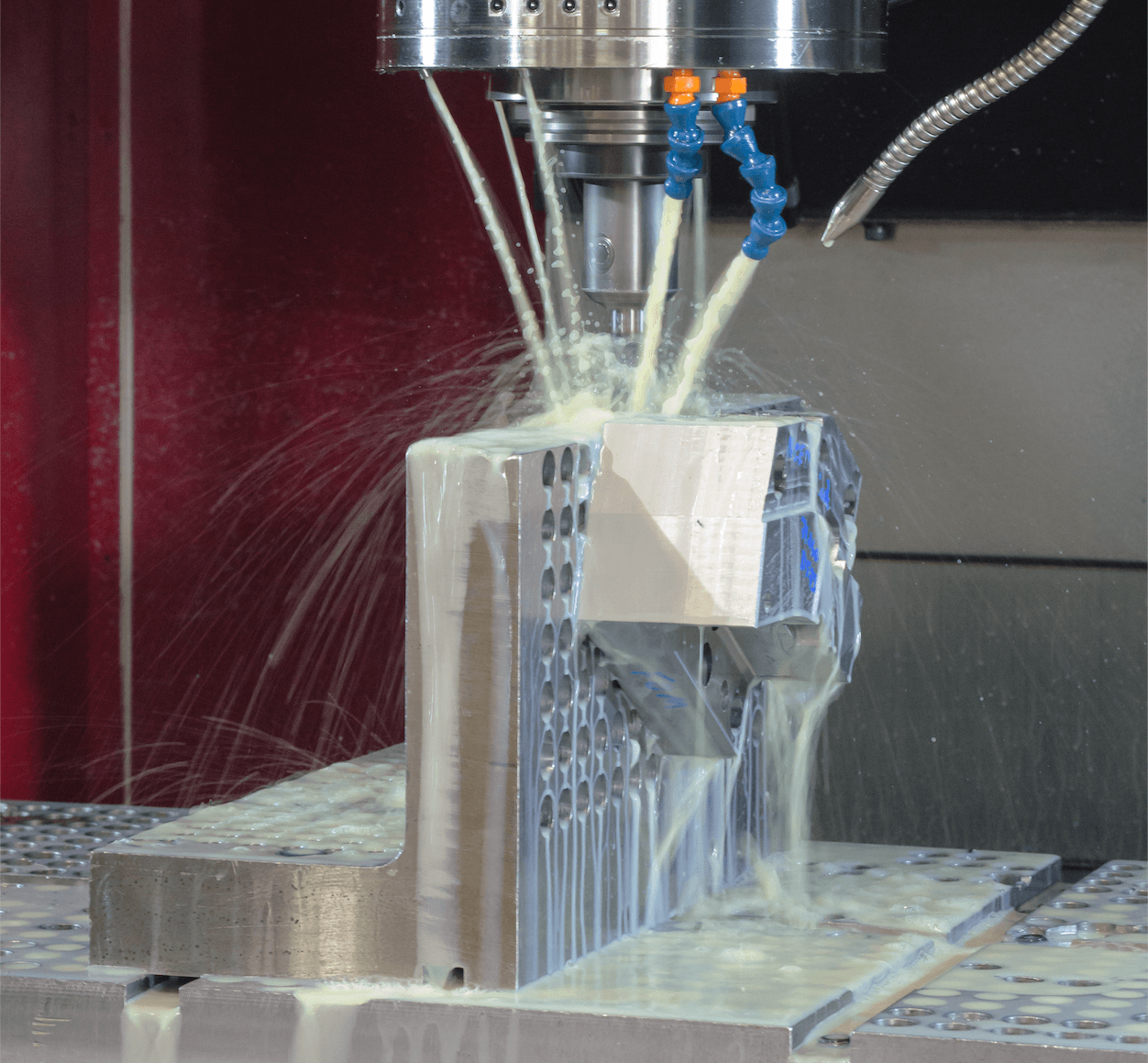

We are very focused on continually improving these areas by constantly testing new tooling, settings and processes to improve our speed, accuracy and reduce costs.

CONTINUALLY IMPROVING

We are always testing new tooling and processes that improve our speed and accuracy.

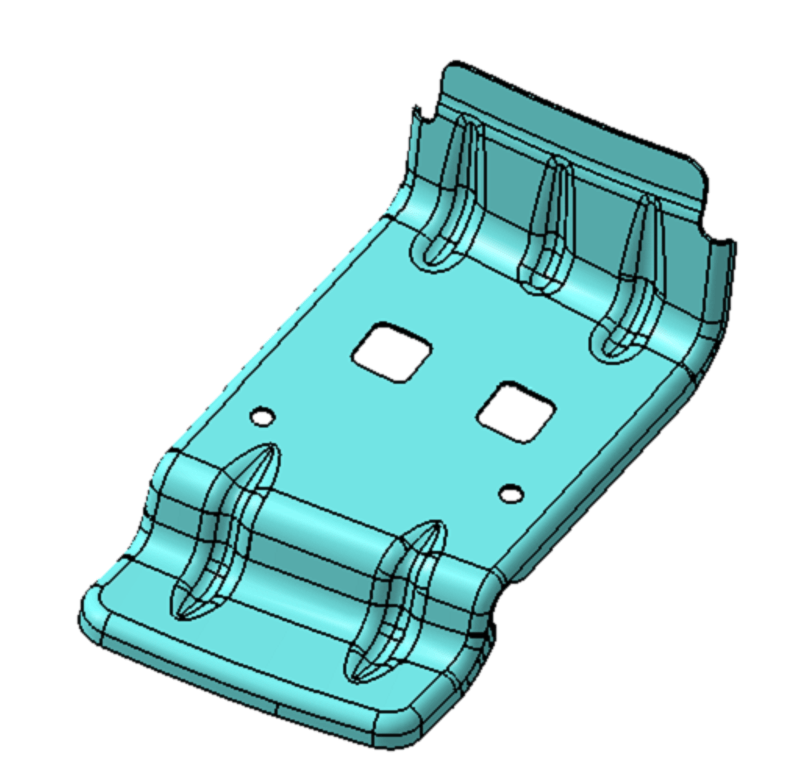

CNC programming

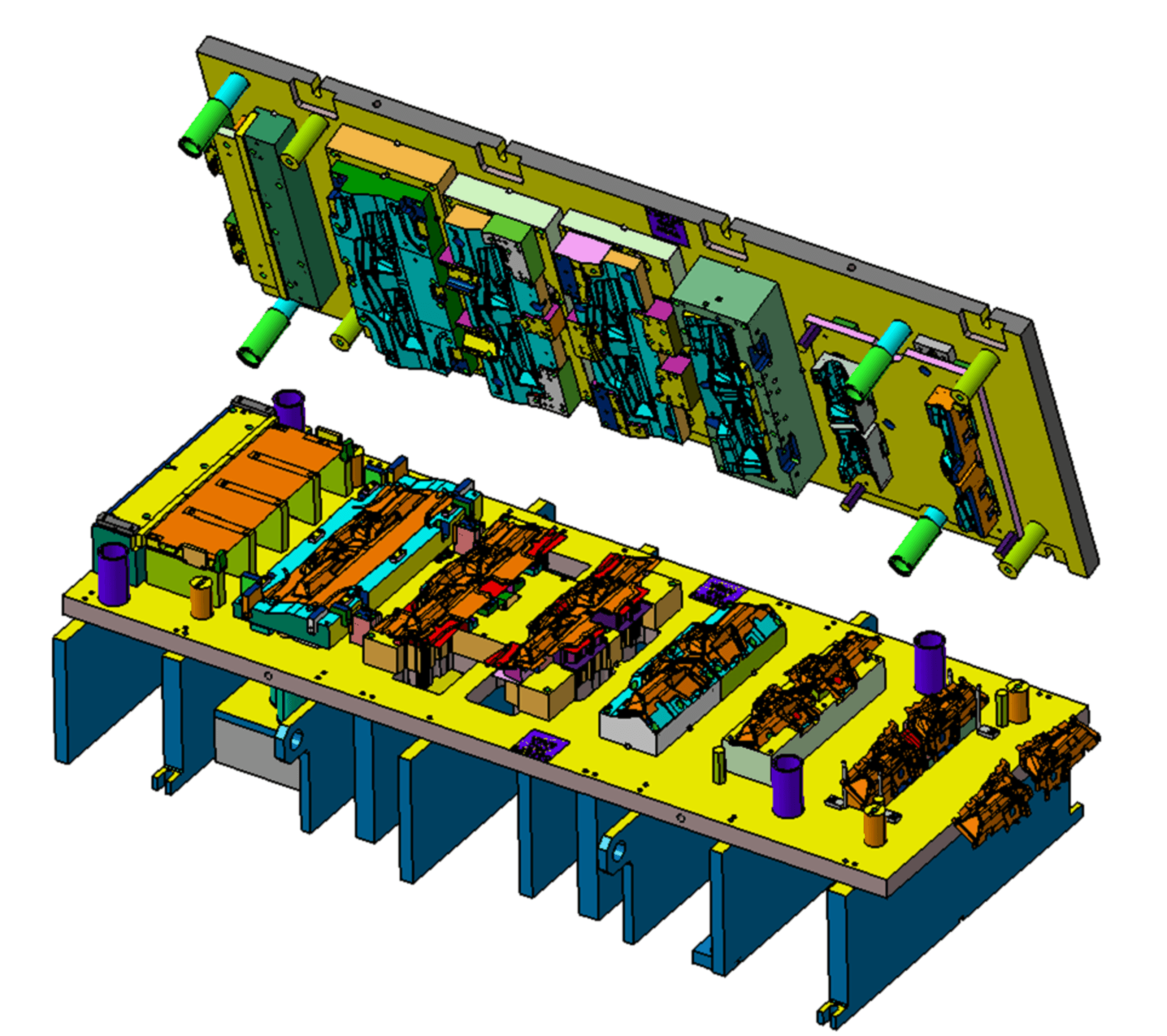

Enterprise currently utilizes 5 CNC centers. Our largest has a machining travel capability of 158 x 98 x 39 inches. Our CNC programming group quickly turns VISI designs into machining programs. The applications feature recognition and automated programming capabilities significantly reduce programming time. Conversely, when complex customized tool paths are required, its robust editing features provide all the control needed to create highly effective machining programs. All CNC programs are simulated prior to being released to production so problems can be corrected without wasting material or valuable machine time. Synchronized engineering standards and our jig-plate set up system provides fast, accurate and repeatable loading and machining.

Precision

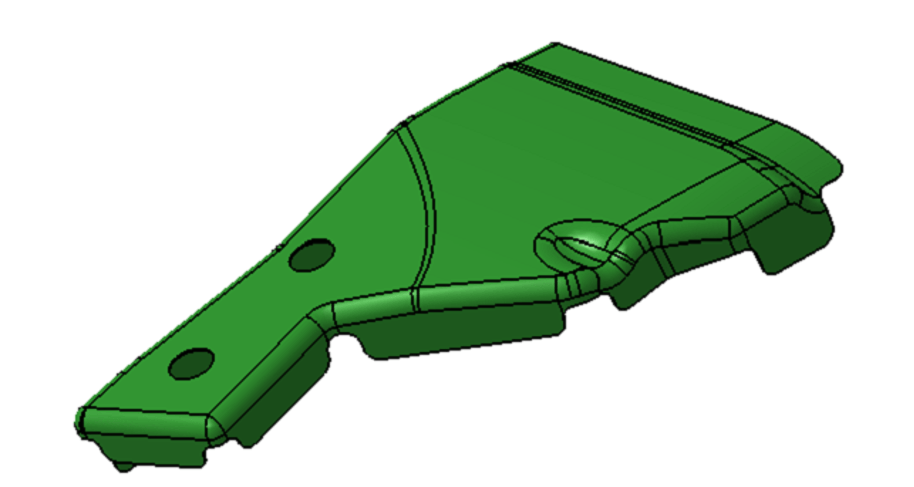

Set up and process steels in state of the art precision machining and wire equipment.

Industry

Industry driven advancements in technology, materials and tooling.