Custom Simulation & Engineering Services

Our Custom Simulation & Engineering

Here at Enterprise, we go beyond providing you with competitive pricing and firm on time delivery commitments.

CUSTOMIZED SERVICES

We deliver the results you want, every step of the way.

Experience

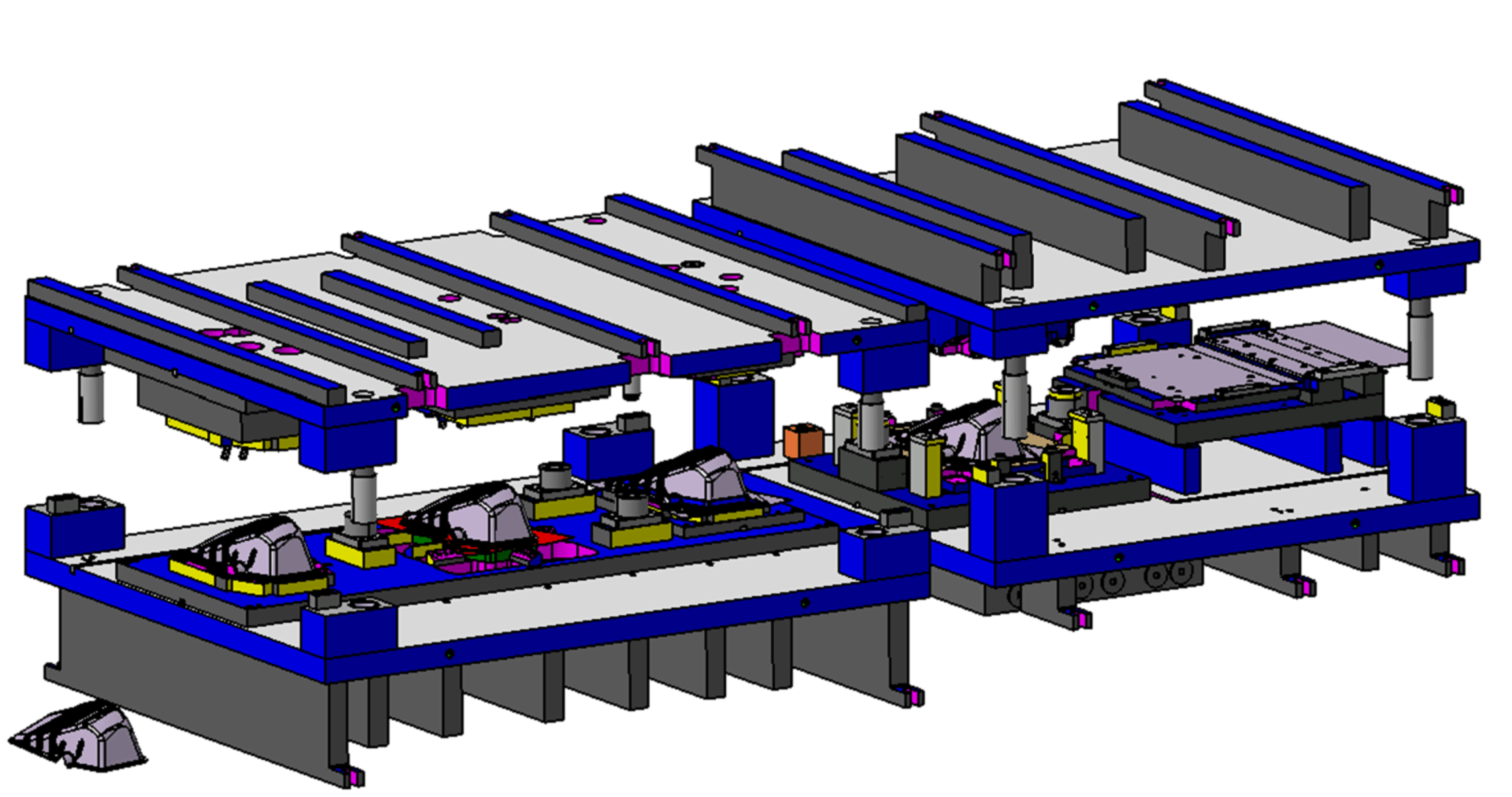

With our team's extensive engineering, technical and die making expertise we are adept at recognizing opportunities and offer alternative processes such as multi-part or interchangeable tooling, to reduce the need for off-line or secondary operations, always focusing on reducing your material usage. Our goal is to always provide you a better value for your dollar. Our experienced advanced engineers have a solid record of adding significant value by identifying improvement opportunities and isolating critical requirements. The potential for improved production quality and consistency, reduced material, lower tooling and maintenance costs, and faster lead-times are a few extra value added benefits that we can provide you by being involved in the early stages of your programs.

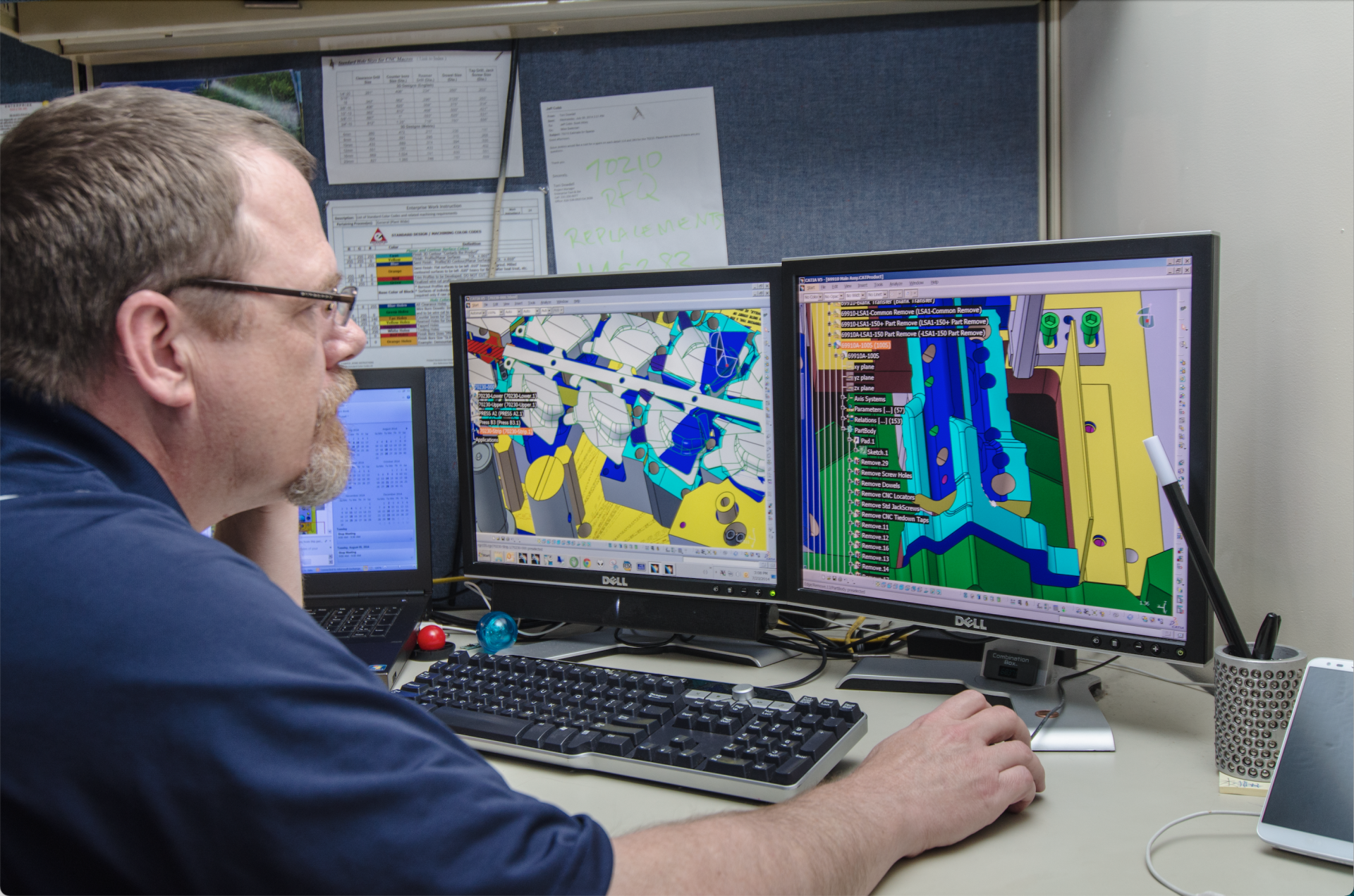

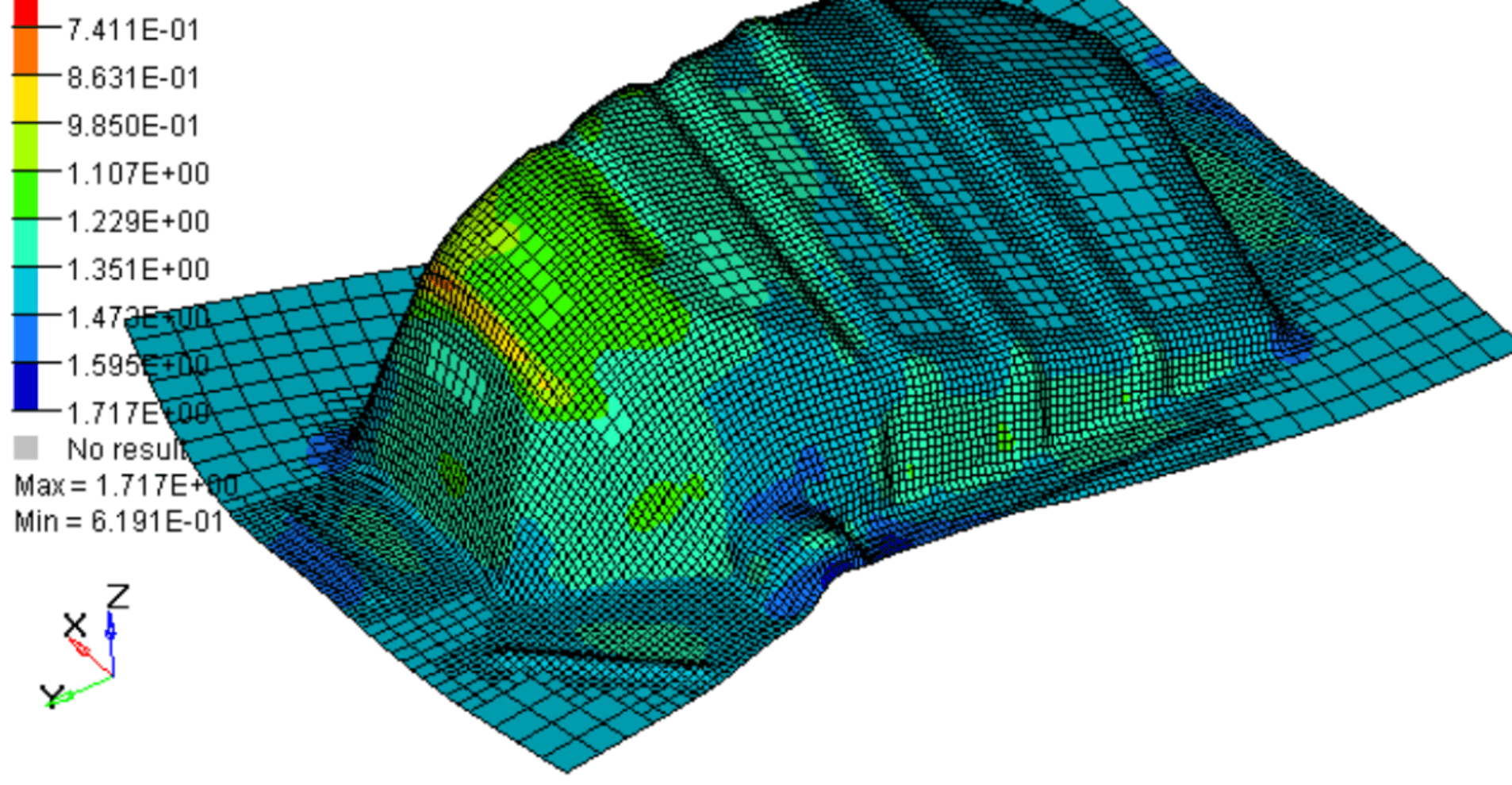

Simulation & Design - VISI

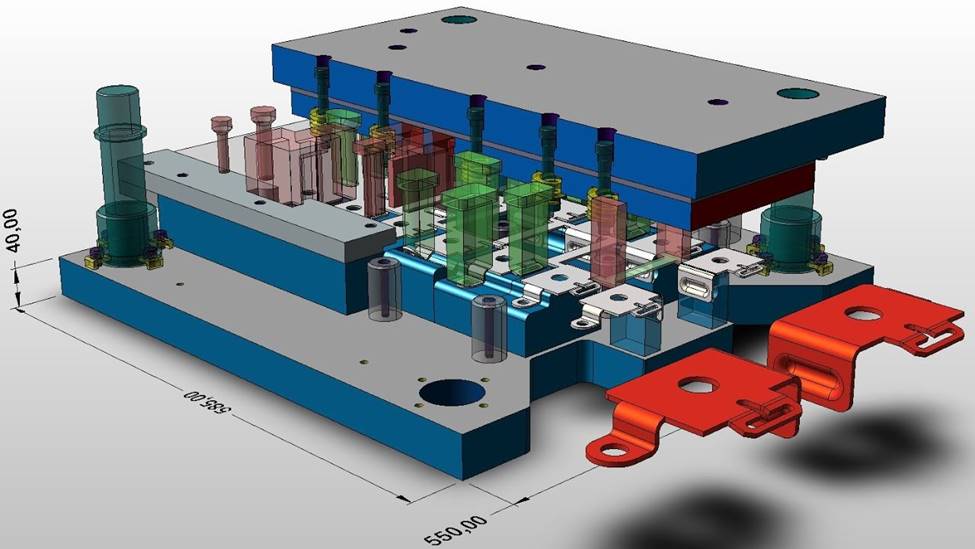

Enterprise has full simulation and design capabilities with cross functional design teams that are utilized to produce the most cost effective and efficient designs. All of our designs are 100% detailed for convenient maintenance & repair. With VISI, all die sections are built precisely to math data though the utilization of CNC processes.

VISI is the foundation of our 3D design process. By combining the software’s powerful features with simulation results, a pre-defined 3D parts catalog, and standard design parameters, our design process capitalizes the benefits of state of the art, integrated technology. The level of visual detail, unlimited viewing perspectives, and parametric modeling provided in VISI enables a very thorough and efficient design review process. When design is completed, the data rich nature of VISI models greatly enhance the speed and accuracy of our CNC programming and machining processes. For the customer, the final “as built” design files provide 100% detailed design record – invaluable for future engineering changes, replacements and repairs.

Engineering & Program Management - The Enterprise Way

- Cutting edge solid modeling and simulation software

- High end performance CAD work stations

- Continuous involvement with engineering and design experts

- Educational opportunities and career path advancement

- Building and maintaining customer relationships

- Managing successful projects = On time and within budget!