Give Us Your

Manufacturing Challenge,

We'll Provide A Solution.

We are committed to provide the results you want and need

Our design expertise and manufacturing capabilities allow us the flexibility to provide cost efficient, customer tailored tooling to meet all of your manufacturing needs. Through our continuous improvement we provide world class tooling at a competitive price! We continually make technical advancements in our industry through capital investments in equipment and educating our staff with the latest technology. This allows us to provide a higher end product – your tooling!

We Are Competitive,

That's Our Advantage

Here at Enterprise, we go beyond providing you with competitive pricing and firm on time delivery commitments. With our teams extensive engineering, technical and die making expertise we are adept at recognizing opportunities and offer alternative processes such as multi-part or interchangeable tooling, to reduce the need for off-line or secondary operations, always focusing on reducing your material usage. Our goal is to always provide you a better value for your dollar.

Our Services

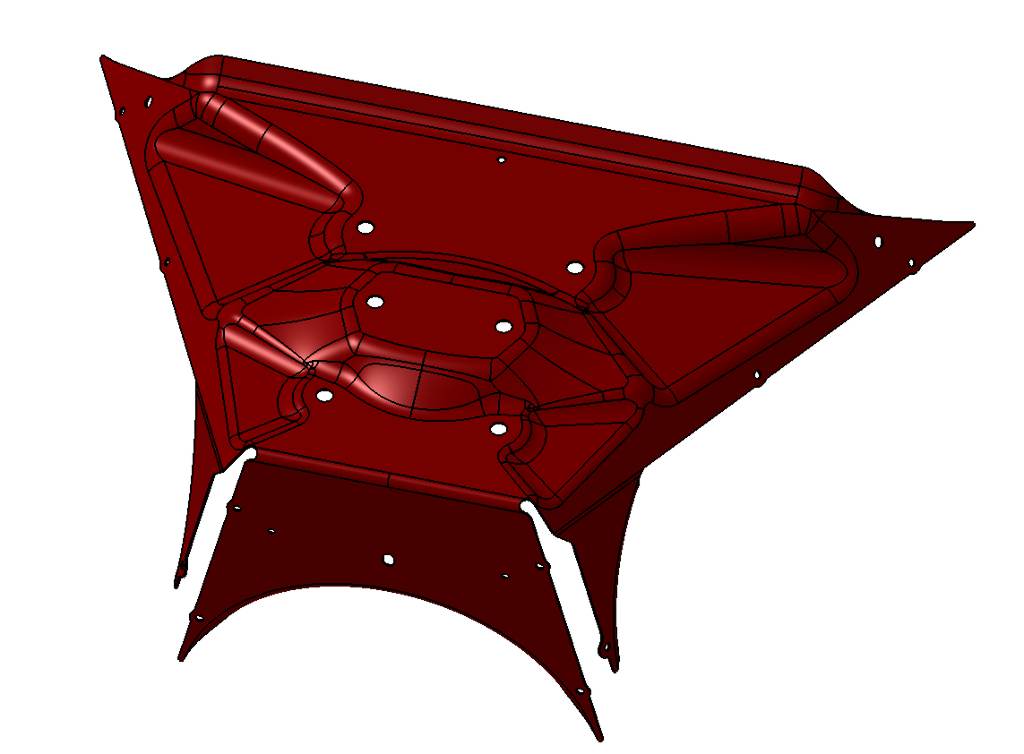

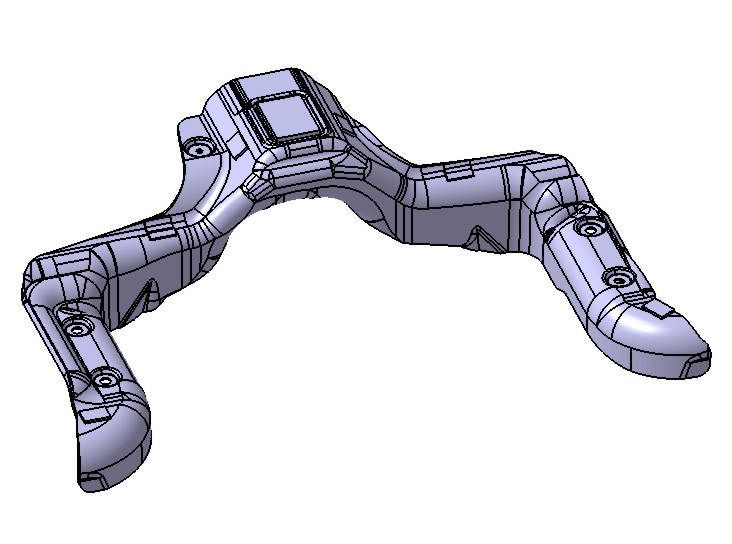

We provide full simulation and design capabilities. Including, Cross functional design teams are utilized to produce the most cost effective and efficient designs. All of our designs are 100% detailed for cost effective and convenient maintenance & repair.

We currently utilizes 5 CNC centers. Our largest has a machining travel capability of 158 x 98 x 39 inches. Our CNC programming group quickly turns VISI designs into machining programs. The applications feature recognition and automated programming capabilities significantly reduce programming time.

Our tryout department consists of 5 tryout presses with capacities of 135 up to 800 tons, with bed sizes ranging from 40” x 60” to 72” x 160”. Three of the presses are equipped with feeders for continuous-run, tryout capability, and the 800T is equipped with a roll-out bolster for quick die changes.